a. VISUAL CHECKS

Before energizing the transformer please make a visual check to be sure that there is any external object inside the transformer, especially in correspondence with LV connection and in cooling ducts. If the transformer has been stored for a long time it’s necessary to control the absence of condensation or dust.

In the event that anomalies are found, please contact our technical department.

b. ELECTRICAL CHECKS

Before connecting HV and LV transformer’s terminal, the following electrical checks have to be performed:

- Do a correct grounding of the transformer (see Fig. 1 point 9)

- Check that the tap-changers are all connected in the same position

- If the transformer has more than one primary voltage it’s necessary to make sure that it is connected on the same voltage available in the network. If not, the tapping links have to be adjusted accordingly.

- It is necessary to check that all the protections are properly installed and adjusted with correct parameters for a prompt action of system protection.

- Accessories operative verification.

- We recommend to control the windings insulation between them and against ground with a megaohmmeter performing the measurements at a voltage of 2.500V. The correct values to be obtained are the following:

- Measurement between HV windings against LV windings and ground: > 20 MΩ

- Measurement between LV windings and ground: > 10 MΩ

If the measured values are lower, please contact our technical department.

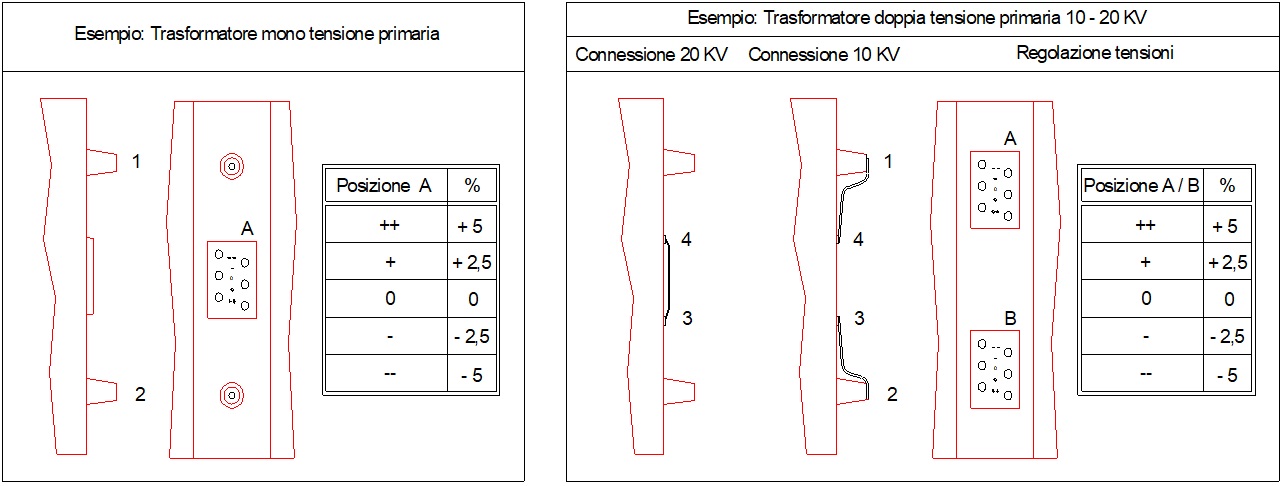

After transformer energization, but before LV load connection, the output voltage has to be checked to make sure that the value is in line with the expected rating output voltage. If the values are different from what expected please de-energize the transformer and, after all the safety check are performed, adjust the tapping links in the proper way to obtain the expected voltage level in accordance with the following diagram (Fig. 13).

Fig. 13

The following formula can be used to understand the proper link to be selected:

(Vm / Vn – 1) x 100 = Value of the regulation to use (%)

Vm is the measured voltage on LV side and Vn is the transformer rated voltage.

The transformer majority is provided with ± 2 X 2,5 % tap changers but other configurations are available.

In case of double primary voltage transformer (for example 10.000-20.000V) two tap changers are available and both of them must be located in the same link position!

In case the tap changer is different and / or different regulation values are present (which are shown in the test report) or for any clarification contact our technical department.All operations performed on the transformer must be carried out with the machine disconnected and made safe!

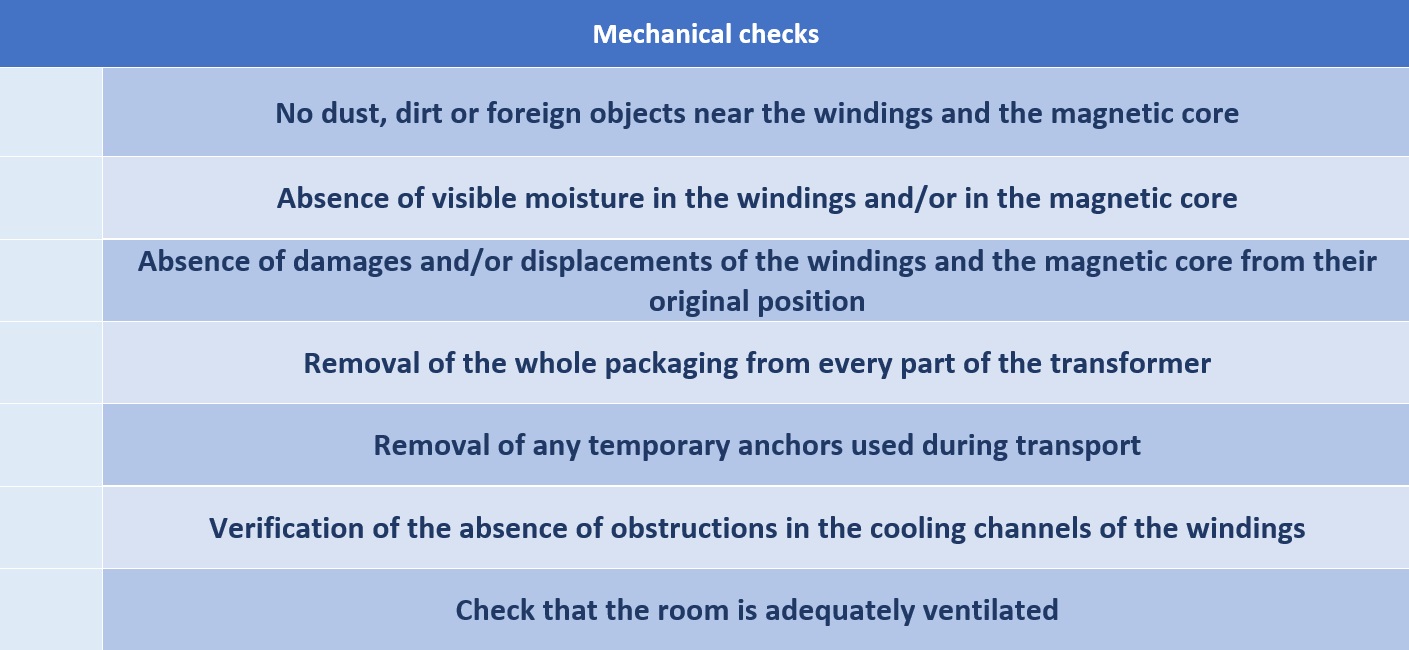

c. MECHANICAL CHECKS

After the transformer positioning into transformer room please perform the following mechanical checks:

- Proper transformer grounding check torque

- Proper Insulating and safety distances check

- Proper tightening of transformer HV and LV terminals and the tap changer.

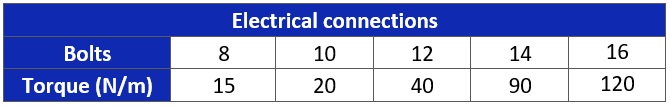

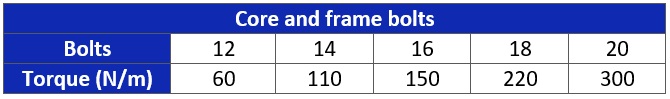

Here follows the table of the suggested tightening torque parameters:

Tab. 5

Tab. 6

kg/m = (N/m) / 9,81.

d. LIST OF FINAL CHECKS

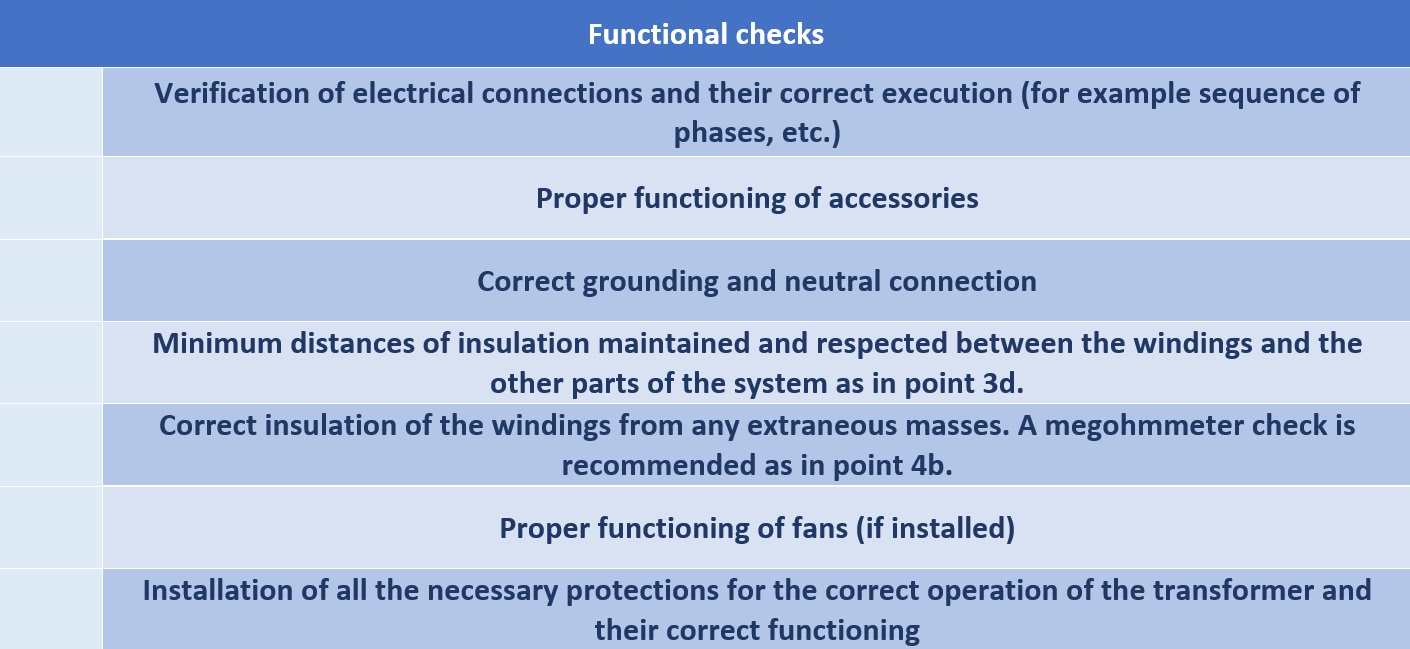

With the following list we indicate the checks to be performed before the effective energizing of the transformer:

Tab. 7

Tab. 8